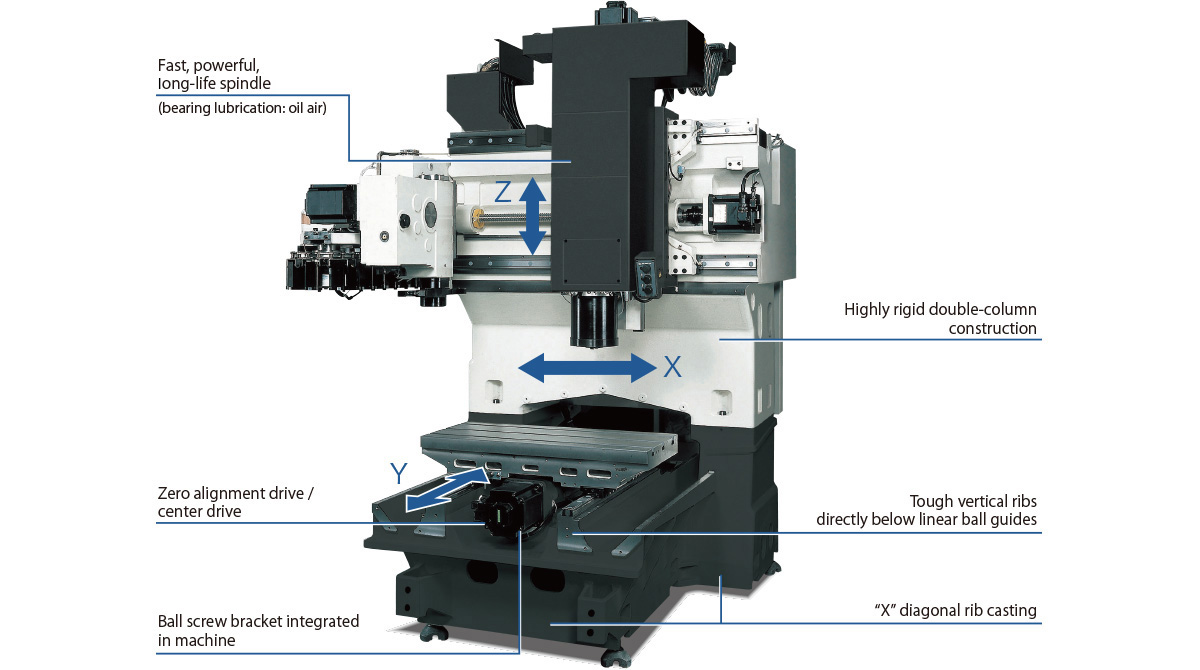

Vertical Machining Centers ACE CENTER MB-V series

- Highly rigid construction for productivity

that exceeds expectations -

- ・Rugged machine structure developed using 3D-CAD and FEM analysis

- ・Same rugged column structure as used in our proven column machining centers

- ・Bearing bracket of feeding axis integrated into the machine

-

- Powerful spindles

provide heavy-duty cutting with ease -

- Cutting capacities

- 504cm3/min(face milling)

672cm3/min(end milling)

| Tool | Spindle min-1 |

Cutting m/ min |

Feedrate mm /min |

Width mm |

Depth mm |

Chips cm3 /min |

|---|---|---|---|---|---|---|

| ø80 face mill 8 blades (cermet) | 895 | 225 | 2,600 | 56 | 2.5 | 364 |

| ø20 roughing end mill, 7 flutes (carbide) |

3,660 | 230 | 4,300 | 4 | 20 | 344 |

| ø50 insert drill | 1,000 | 157 | 150 | - | - | - |

| Tap M30P3.5 | 318 | 30 | 1,113 | - | - | 60% (Spindle load) |

(Workpiece material: S45C)

| Tool | Spindle min-1 |

Cutting m/min |

Feedrate mm/min |

Width mm |

Depth mm |

Chips cm3/min |

|---|---|---|---|---|---|---|

| ø80 face mill 8 blades (cermet) | 895 | 225 | 3,000 | 56 | 3 | 504 |

| ø20 roughing end mill, 7 flutes (carbide) |

4,000 | 251 | 4,800 | 7 | 20 | 672 |

| ø63 insert drill | 720 | 142 | 108 | - | - | - |

| Tap M30P3.5 | 318 | 30 | 1,113 | - | - | 66% (Spindle load) |

(Workpiece material: S45C)

| Tool | Spindle min-1 |

Cutting m/min |

Feedrate mm/min |

Width mm |

Depth mm |

Chips cm3/min |

|---|---|---|---|---|---|---|

| ø80 face mill 8 blades (cermet) | 895 | 225 | 3,000 | 56 | 3 | 504 |

| ø20 roughing end mill, 7 flutes (carbide) |

4,000 | 251 | 2,800 | 12 | 20 | 672 |

| ø63 insert drill | 909 | 180 | 137 | - | - | - |

| Tap M36P4 | 106 | 12 | 424 | - | - | - |

(Workpiece material: S45C)