Turning Centers with Twin Spindles TWIN STAR LT EX series

- Achieve ideal balance for 1-2 processes

-

- Highly efficient machining with spindles with same capacity on left and right

- Left and right spindles equipped with high accuracy integral motor/spindles make part transfer possible during spindle operation with synchronized C axis control.

-

LT2000 EX LT3000 EX Spindle motor 11.5/7.5 kW

(5 min/cont)22/15 kW

(30 min/cont)Bar dia Standard spindle ø51mm ø65mm*2 Big-Bore spindle ø65mm*1 ø80mm - *1. Left spindle only

- *2. Up to ø69 mm is possible with 10-inch chuck.

- Note: The chuck/cylinder used may limit machinable bar diameters.

- Turrets with the same upper and lower capacity enable full process-intensive machining

- V16 turrets are used on both top and bottom to handle complex shape, multi-process, high mix production. Setup change time can be shortened with permanent tool sets.

-

LT2000 EX LT3000 EX Milling-tool spindle motor 5.5/3.7 kW

(2 min/cont)7.1/4.1 kW

(25 min/cont)Rapid traverse X axis: 30 m/min, Z axis: 40 m/min

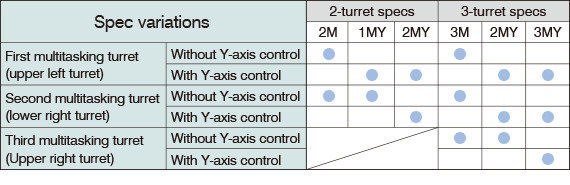

- Achieve the best production system with our abundant lineup

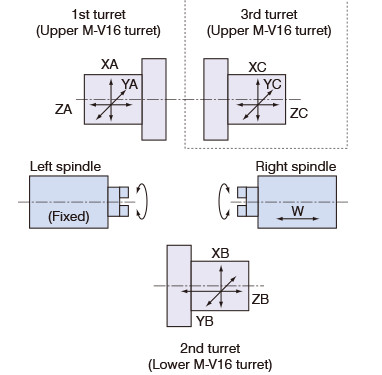

- Achieve even greater productivity and process-intensive machining by selecting specifications matched to use, such as simultaneous machining with 3 upper/lower turrets or simultaneous upper/lower Y-axis machining.

-

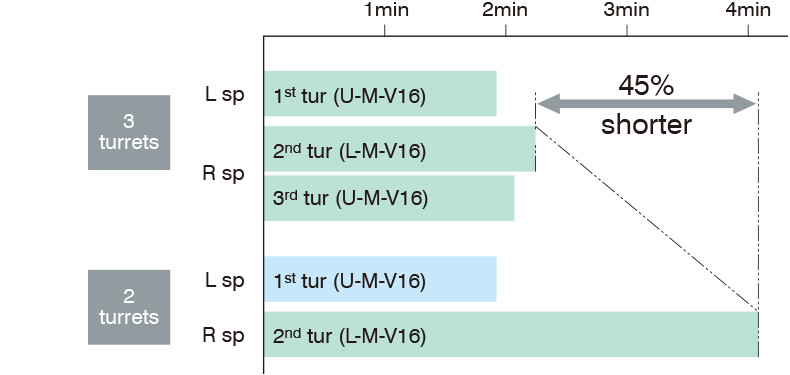

- Minimize takt time with third turret (Optional)

- Well-balanced cycle times achieved with simultaneous machining using upper left and right turrets and lower turret. Cycle times can be significantly shortened.

-

- Y-axis specifications (Optional) added on all turrets

- Simultaneous upper/lower Y-axis machining possible.

-

LT2000 EX LT3000 EX Y-axis travel 95 mm

YA, YB, YC: +50 to −45125 mm

YA, YB, YC: +70 to −55

Machine Specifications

| Model | LT2000 EX | |||||||

|---|---|---|---|---|---|---|---|---|

| 2-turret specs | 3-turret specs | |||||||

| 2M | 1MY | 2MY | 3M | 2MY | 3MY | |||

| Capacity | Swing over saddle | mm (in.) | ø400 (ø15.75) | |||||

| Max machining dia × length*1 |

mm (in.) | ø210 × L130 (ø8.28 × L5.12) | ||||||

| Distance between noses | mm (in.) | 960 (37.80) | 990 (38.98) | |||||

| Travel | X axis | mm (in.) | XA, XB: 205 (+175 to −30) (8.07 (+6.89 to −1.18)) | XA, XB, XC: 205 (+175 to −30) (8.07 (+6.89 to −1.18)) | ||||

| Z axis | mm (in.) | ZA, ZB: 700 (27.56), W: 730 (28.74) | ZA, ZC: 400 (15.75), ZB: 730 (28.74), W: 760 (29.92) | |||||

| Y axis | mm (in.) | - | YA: 95 (3.74) (+50 to −45) (+1.97 to −1.77) |

YA, YB: 95 (3.74) (+50 to −45) (+1.97 to −1.77) |

- | YA, YB: 95 (3.74) (+50 to −45) (+1.97 to −1.77) |

YA, YB, YC: 95 (3.74) (+50 to −45) (+1.97 to −1.77) |

|

| C axis | deg | 360 (minimum control angle 0.001) | ||||||

| Spindle (L/R) | Speed | min-1 | 50 to 6,000 [50 to 5,000 (Left spindle only)] | |||||

| Speed ranges | 2 auto ranges (motor coil switching, 2 ranges) | |||||||

| Spindle nose | ø140 flat [JIS A2-6 (Left spindle only)] | |||||||

| Spindle bore / Front bearing ID |

mm (in.) | ø62/100 (ø2.44/3.94) [ø80/120 (ø3.15/4.72) (Left spindle only)] | ||||||

| Turret | Type | Multitasking V16 [V12] | ||||||

| No. of tools | 16 [12] (L, M) | |||||||

| OD tool shank | mm (in.) | □20/ø32 (□0.79/ø1.26) | ||||||

| Milling tool spindle speed | min-1 | 45 to 6,000 | ||||||

| Rapid traverse | X axis | m/min (ipm) | 30 (1,181) | |||||

| Z axis | m/min (ipm) | 40 (1,575) | ||||||

| Y axis | m/min (ipm) | - | 15 (591) | - | 15 (591) | |||

| W axis | m/min (ipm) | 32 (1,260) | ||||||

| C axis | min-1 | 200 | ||||||

| Motors | Main spindles | kW (hp) | L/R: 11.5/7.5 (15.3/10) [22/15 (30/20)] (5 min/cont) | |||||

| Milling tool | kW (hp) | 5.5/3.7 (7.5/5) (2 min/cont) | ||||||

| X axis | kW (hp) | XA: 3.5 (4.7), XB: 3.0 (4) | XA, XC: 3.5 (4.7), XB: 3.0 (4) | |||||

| Z axis | kW (hp) | ZA, ZB: 3.5 (4.7) | ZA, ZB, ZC: 3.5 (4.7) | |||||

| Ys axis | kW (hp) | - | YsA: 3.5 (4.7) | YsA: 3.5 (4.7) YsB: 2.2 (3) |

- | YsA: 3.5 (4.7) YsB: 2.2 (3) |

YsA, YsC: 3.5 (4.7) YsB: 2.2 (3) |

|

| Coolant motor (50/60 Hz) | kW (hp) | 0.55/0.75 (0.7/1) × 3 | 0.55/0.75 (0.7/1) × 4 | |||||

| Machine size | Height | mm (in.) | Side discharge: 2,285 (89.96) Rear discharge: 2,435 (95.87) |

Side discharge: 2,301 (90.59) Rear discharge: 2,451 (96.50) |

Side discharge: 2,285 (89.96) Rear discharge: 2,435 (75.87) |

Side discharge: 2,301 (90.59) Rear discharge: 2,451 (96.50) |

||

| Floor space (including tank) | mm × mm (in.) | Side discharge: 3,745 × 2,464 (147.44 × 97.01), Rear discharge: 3,231 × 3,417 (127.20 × 134.53) | ||||||

| Weight (with CNC) | kg (Ib) | 8,500 (18,700) | 9,000 (19,800) | 9,300 (20,460) | 9,800 (21,560) | |||

| CNC | OSP-P300LA | |||||||

*1: Rough dimensions for work lengths that can be axially milled simultaneously on 2 turrets

[ ] Optional

| Model | LT3000 EX | |||||||

|---|---|---|---|---|---|---|---|---|

| 2-turret specs | 3-turret specs | |||||||

| 2M | 1MY | 2MY | 3M | 2MY | 3MY | |||

| Capacity | Swing over saddle | mm (in.) | ø550 (ø21.66) | |||||

| Max machining dia × length*1 |

mm (in.) | ø350 × L200 (ø13.78 × L7.88) | ||||||

| Distance between noses | mm (in.) | 1,200 (47.25) | ||||||

| Travel | X axis | mm (in.) | XA, XB: 255 (+225 to −30) (10.04 (+8.86 to −1.18)) | XA, XB, XC: 255 (+225 to −30) (10.04 (+8.86 to −1.18)) | ||||

| Z axis | mm (in.) | ZA, ZB: 930 (36.61), W: 940 (37.01) | ZA, ZC: 480 (18.90), ZB: 930 (36.61), W: 940 (37.01) | |||||

| Y axis | mm (in.) | - | YA: 125 (4.92) (+70 to −55) (+2.76 to −2.17) |

YA, YB: 125 (4.92) (+70 to −55) (+2.76 to −2.17) |

- | YA, YB: 125 (4.92) (+70 to −55) (+2.76 to −2.17) |

YA, YB, YC: 125 (4.92) (+70 to −55) (+2.76 to −2.17) |

|

| C axis | deg | 360 (minimum control angle 0.001) | ||||||

| Spindle (L/R) | Speed | min-1 | 45 to 5,000 [45 to 4,200] | |||||

| Speed ranges | 2 auto ranges (motor coil switching, 2 ranges) | |||||||

| Spindle nose | A2-6 [A2-8] | |||||||

| Spindle bore / Front bearing ID |

mm (in.) | ø80/120 (ø3.15/4.72) [ø91/140 (ø3.58/5.51)] | ||||||

| Turret | Type | Multitasking V16 [V12] | ||||||

| No. of tools | 16 [12] (L, M) | |||||||

| OD tool shank | mm (in.) | □25/ø40 (□0.98/ø1.57) | ||||||

| Milling tool spindle speed | min-1 | 45 to 6,000 | ||||||

| Rapid traverse | X axis | m/min (ipm) | 30 (1,181) | |||||

| Z axis | m/min (ipm) | 40 (1,575) | ||||||

| Y axis | m/min (ipm) | - | 20 (787) | - | 20 (787) | |||

| W axis | m/min (ipm) | 40 (1,575) | ||||||

| C axis | min-1 | 200 | ||||||

| Motors | Main spindles | kW (hp) | L/R: 22/15 (30/20) [30/22 (40/30)] (30 min/cont) | |||||

| Milling tool | kW (hp) | 7.1/4.1 (9.5/5.5) (25 min/cont) | ||||||

| X axis | kW (hp) | XA, XB: 3.5 (4.7) | XA, XB, XC: 3.5 (4.7) | |||||

| Z axis | kW (hp) | ZA, ZB: 3.5 (4.7) | ZA, ZB, ZC: 3.5 (4.7) | |||||

| Ys axis | kW (hp) | - | YsA: 3.5 (4.7) | YsA: 3.5 (4.7) YsB: 2.2 (3) |

- | YsA: 3.5 (4.7) YsB: 2.2 (3) |

YsA, YsC: 3.5 (4.7) YsB: 2.2 (3) |

|

| Coolant motor (50/60 Hz) | kW (hp) | 0.55/0.75 (0.7/1) × 3 | 0.55/0.75 (0.7/1) × 4 | |||||

| Machine size | Height | mm (in.) | Side discharge: 2,650 (104.33) Rear discharge: 2,750 (108.27) |

|||||

| Floor space (including tank) | mm × mm (in.) | Side discharge: 4,504 × 2,750 (177.32 × 108.27), Rear discharge: 3,994 × 3,743 (157.24 × 147.36) | ||||||

| Weight (with CNC) | kg (Ib) | 11,200 (24,640) | 12,600 (27,720) | |||||

| CNC | OSP-P300LA | |||||||

*1: Rough dimensions for work lengths that can be axially milled simultaneously on 2 turrets

[ ] Optional