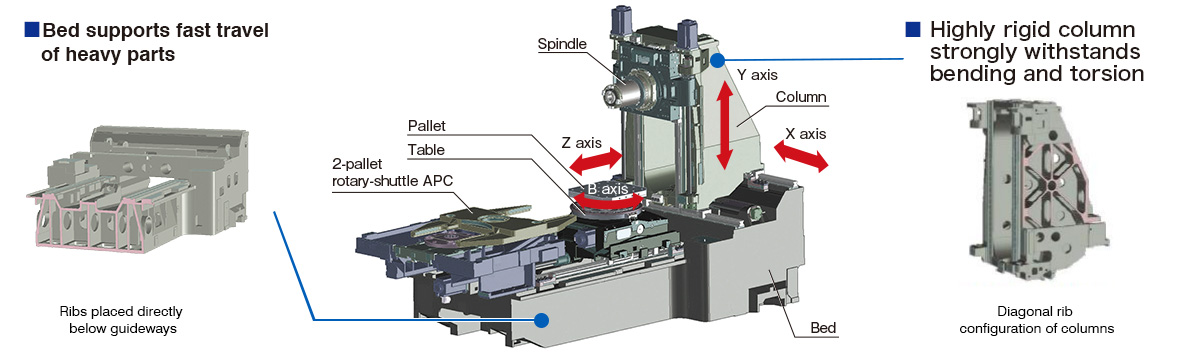

- Machine structure for high speed feed and high rigidity

-

- Highly rigid 3-point supported bed

- Easy installation thanks to bed that does not twist.

- Supporting stable, high accuracy over a long period.

- Ball screw bracket

- The ball screw brackets at both ends of the X-Y-Z axes are reinforced and combined for highly accurate drive and positioning.

- Ball screw cooling

- X-Z axis ball screw cooling and Y-axis motor bracket cooling are standard. Assuring stable accuracy during high rates of operation.

- Indexing table, pallet

- Indexing table uses curvic coupling for high-accuracy indexing.

- Std: 1 degree

- Opt: NC 0.001°

- Pallet seating surface uses a taper cone system for high accuracy positioning and high durability.

- Indexing table uses curvic coupling for high-accuracy indexing.

- Highly rigid 3-point supported bed

-

- High-speed operation that reduces non-cutting time

-

-

- Rapid traverse:

- 60 m/min (X-Y-Z axes)

-

- Rapid acceleration:

- 0.7G (maximum)

-

- Tool change:

- 2.0 sec (T-T)

- 4.4 sec (C-C)

-

- Table indexing:

- 2.0 sec (MA-600HⅡ 1 degree indexing 90 degrees)

- 2.5 sec (MA-600HⅡ 0.001 degree indexing 90 degrees)

-

- APC time:

- 12 sec (MA-600HⅡ)

-

- Ideal performance levels from a variety of

spindles for a wide range of applications - Highly efficient production with high machining capacity

-

-

- Machining capacity

-

901cm3/min (MA-500HⅡ actual data*1)

Standard spindle: 6,000 min-1 ø100 face mill Material: S45C

Tool Spindle speed

min-1Cutting

m/

minFeedrate

mm

/minCut width

mmCut depth

mmChips

cm3

/minø100 face mill 10 blades (carbide) 955 300 3,220 70 4 901 ø50 porcupine cutter (carbide) 1,146 180 500 25 50 625 ø63 insert drill (carbide) 606 120 121 - - - M42 P4.5 tap 91 12 409.5 - - 81%* * Spindle load

-

802cm3/min (MA-600HⅡ actual data*1)

Wide-range spindle: 12,000 min-1 ø100 face mill Material: S45C

Tool Spindle speed

min-1Cutting

m/

minFeedrate

mm

/minCut width

mmCut depth

mmChips

cm3

/minø100 face mill 10 blades (carbide) 955 300 2,865 70 4 802 ø50 porcupine cutter (carbide) 1,146 180 400 25 50 500 ø63 insert drill (carbide) 606 120 91 - - - M42 P4.5 tap 91 12 409.5 - - - -

1,081cm3/min (MA-600HⅡ actual data*1)

Super-heavy spindle: 6,000 min-1 (Optional) ø200 face mill Material: S45C

Tool Spindle speed

min-1Cutting

m/

minFeedrate

mm

/minCut width

mmCut depth

mmChips

cm3

/minø200 face mill 10 blades (cermet) 330 207 1,404 140 5.5 1,081 *1. The data shown here represent "actual data," which may not be obtained under different specifications, tooling, cutting, and other conditions.

- Outstanding dimensional stability

with long-run machining of large workpieces - Manageable Deformation—Accurately Controlled

Thermo-Friendly Concept -

Dimensional changes of less than 8μm over time in a wide machining range (actual data with room temperature change of 8°C [TAS-C applicable])

In addition to maintaining high dimensional accuracy when room temperature changes, Okuma's Thermo-Friendly Concept provides high dimensional accuracy during machine startup and machining restart.

To stabilize thermal deformation, warming-up time is shortened and the burden of dimensional correction during machining restart is reduced.

Machine Specifications

| Item | Unit | MA-500HⅡ | MA-600HⅡ | |||

|---|---|---|---|---|---|---|

| No. 50 | No. 40*1 | No. 50 | No. 40*1 | |||

| Travels | X-axis travel (column left/right) |

mm (in.) | 700 (27.56) | 1,000 (39.37) | ||

| Y-axis travel (spindle up/down) |

mm (in.) | 900 (35.43) | ||||

| Z-axis travel (table front/back) |

mm (in.) | 780 (30.71) | 1,000 (39.37) | |||

| Spindle center to pallet top | mm (in.) | 50 to 950 (1.97 to 37.40) | ||||

| Spindle nose to pallet center | mm (in.) | 70 to 850 (2.76 to 33.46) | 70 to 1,070 (2.76 to 42.13) | |||

| Pallet | Work area | mm (in.) | 500 × 500 (19.69 × 19.69) | 630 × 630 (24.80 × 24.80) | ||

| Max load capacity | kg (lb) | 800 [1,000] (1,760 [2,200]) | 1,200 [1,400] (2,640 [3,080]) | |||

| Indexing angle | deg | 1 [0.001] | ||||

| Max workpiece dimensions | mm (in.) | ø800 × 1,000 (ø31.50 × 39.37) | ø1,000 × 1,000 (ø39.37 × 39.37) | |||

| Spindle | Spindle speed | min-1 | 50 to 6,000[50 to 6,000(Super-heavyspindle), 50 to12,000] | 50 to 15,000, 50 to 20,000 | 50 to 6,000[50 to 6,000,(Super-heavyspindle), 50 to12,000, 20,000] | 50 to 15,000, 50 to 20,000 |

| Tapered bore | 7/24 taper No. 50[HSK-A100] | 7/24 taper No. 40, HSK-A63*2 | 7/24 taper No. 50[HSK-A100]*3 | 7/24 taper No. 40, HSK-A63*2 | ||

| Bearing dia | mm (in.) | ø100 (ø3.94) | ø70 (ø2.76) | ø100 (ø3.94) | ø70 (ø2.76) | |

| Feedrate | Rapid traverse | m/min (ipm) | X-Y-Z: 60 (2,362) | |||

| Cutting feed | mm/min (ipm) | X-Y-Z: 1 to 60,000 (0.04 to 2,362) | ||||

| Motors | Spindle (10 min/cont) *4 | kW (hp) | 30/22[45/37*4, 37/26](40/30[60/50, 50/35]) | 26/18.5, 30/22(35/25, 40/30) | 30/22 [45/37*4,37/26, 55/50*5](40/30 [60/50,50/35, 75/66]) | 26/18.5, 30/22(35/25, 40/30) |

| Feed axis motors | kW (hp) | X: 4.6 (6.13), Y: 4.6 (6.13) × 2, Z: 4.6 (6.13) | X: 4.6 (6.13), Y: 4.6 (6.13) × 2, Z: 5.2 (6.93) | |||

| Table indexing | kW (hp) | 3.5 (4.67) | ||||

| ATC | Tool shank | MAS403 BT50[HSK-A100] | MAS 403 BT40, HSK-A63*2 | MAS403 BT50[HSK-A100]*3 | MAS 403 BT40, HSK-A63*2 | |

| Pull stud | MAS-2 [–] | |||||

| Magazine capacity | tools | 40 [60, 81, 111, 141, 171, 195, 225, 255, 285, 320, 400] | ||||

| Max tool dia (w/ adjacent) *6 |

mm (in.) | ø140 (5.51) | ø100 (3.94) | ø140 (5.51) | ø100 (3.94) | |

| Max tool dia (w/o adjacent) *6 |

mm (in.) | ø240 (9.45) | ø150 (5.91) | ø240 (9.45)*7 | ø150 (5.91) | |

| Max tool length | mm (in.) | 450 (17.72) | 450 (17.72) | 450 [600] (17.72 [23.62]) | 450 (17.72) | |

| Max tool weight | kg (lb) | 25 (55) | 10 (22) | 25 (55) | 10 (22) | |

| Tool selection | Memory random (Fixed with 81 or more tools) | |||||

| Machine size | Height | mm (in.) | 3,174 (124.96) | |||

| Floor space; width x depth | mm (in.) | 3,110 × 5,971 (122.44 × 235.08) | 3,410 × 6,495 (134.25 × 255.71) | |||

| Weight | kg (lb) | 21,500 (47,300) | 24,500 (53,900) | |||

| Controller | OSP-P300MA | |||||

[ ]: Optional

*1. No. 40 spindle is optional.

*2. 20,000 min-1 with HSK-A63 only

*3. 20,000 min-1 with HSK-A100 only

*4. Super-heavy spindle motor rating is 20 min/cont (for heavy-duty cutting)

*5. 20,000 min-1 spindle motor rating is 30 min/cont

*6. Values differ with a matrix magazine. Please inquire.

*7. With MA-600HⅡ 20,000 min-1, the maximum tool diameter is limited depending on the spindle speed used.