Solid performance achieved by advanced structural designs

-

- Double column structure handles heavy-duty cutting

- Double-column construction with square columns maintains good rigidity with respect to vertical loads, horizontal loads, and torsion for heavy-duty cutting with high accuracy.

-

-

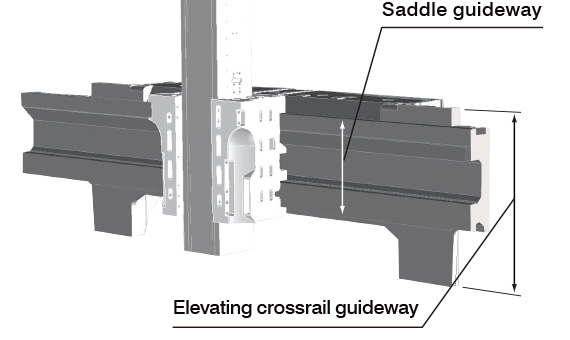

- Elevating crossrail guideway

- The elevating crossrail has sufficient length and a structure for accuracy and long life with no "snaking" movement.

-

-

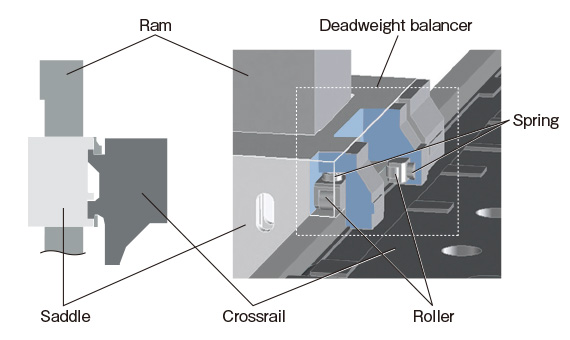

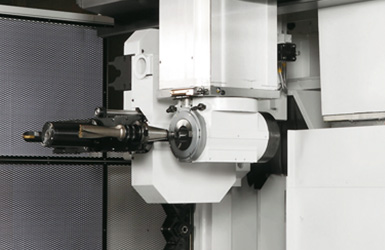

- Spindlehead provides both high speed and high accuracy (ram saddle guideway)

- The spindlehead guide has a wide, highly rigid rectangular cross section, and is supported by a deadweight balancer via rollers on the crossrail. This gives high speed, high accuracy movements and high quality machined surfaces.

-

-

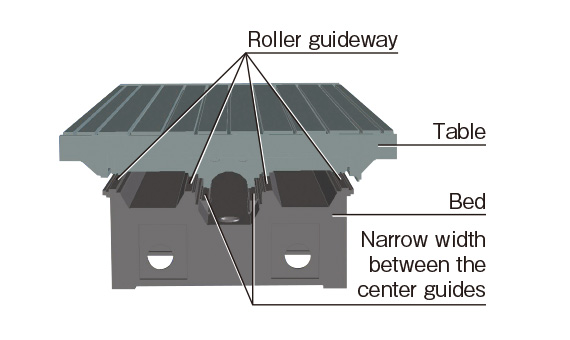

- Smooth, accurate positioning

Table guideway has roller guide system - The weight of the table and workpiece is supported with roller bearings on hardened and ground surfaces. Movement is not affected by weight changes from heavy workpiece loads,

enabling light, smooth movements and accurate positioning.

Layout includes the drive system (ball screw) in the table center with a narrow width between the center guides, to achieve outstanding linear motion straightness and long-term stability. -

- Smooth, accurate positioning

- Automation for highly productive and flexible performance

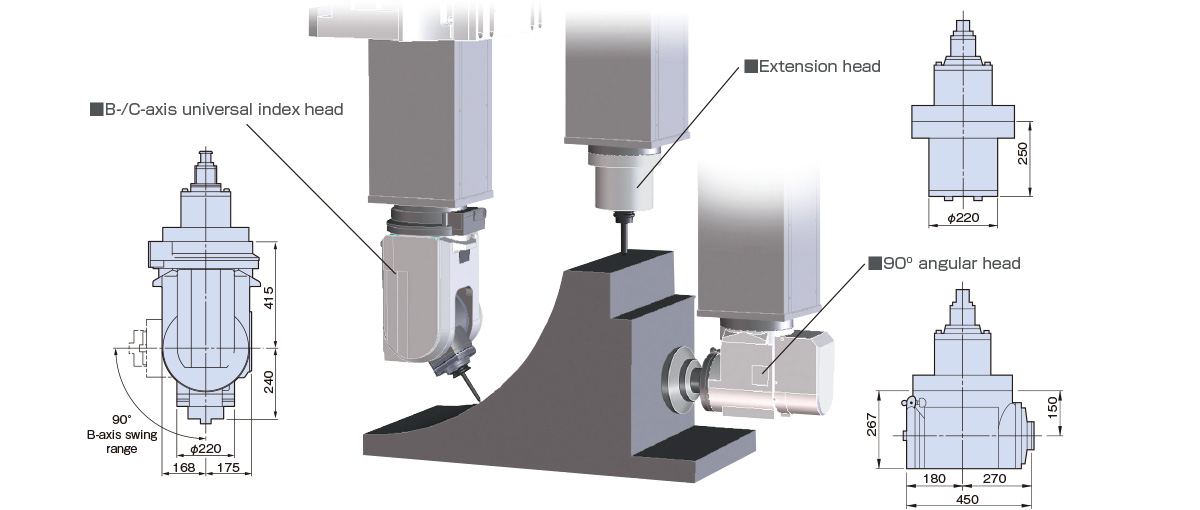

- Full array of heads

-

All types of cutting in all types of shapes can be machined by changing the wide array of heads.

Many different processes can be performed in auto operation with the auto tool changer (ATC) and auto head changer (AAC).

- Fast NC-ATC

-

One arm performs the changes for both the horizontal and vertical spindles. The next tool to be used, regardless of the spindle location, is brought to the standby position during cutting. This simultaneous operation greatly reduces

tool-to-tool time.

ATC is available for 30°angular heads and universal index heads (B/C axis) in addition to extension heads and 90° angular heads.

-

Extension head tool change -

90º angular head tool change -

Universal index head tool change

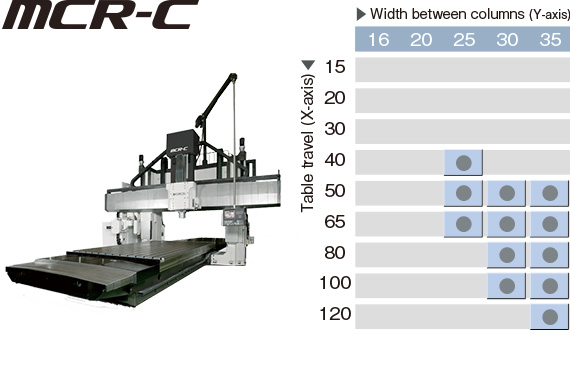

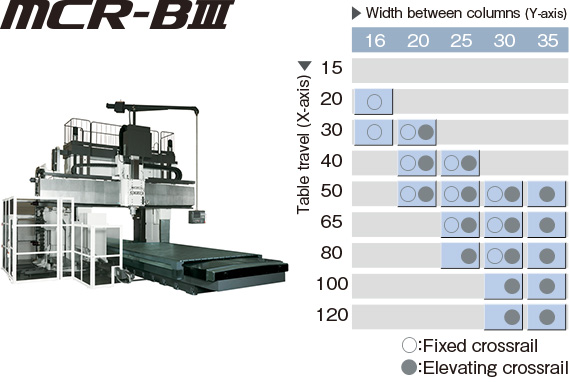

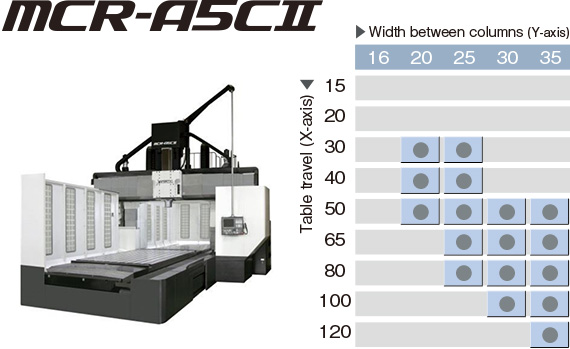

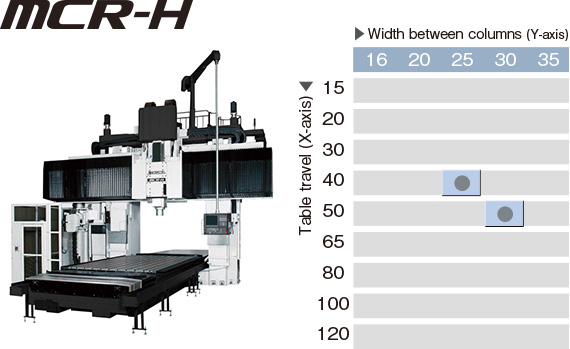

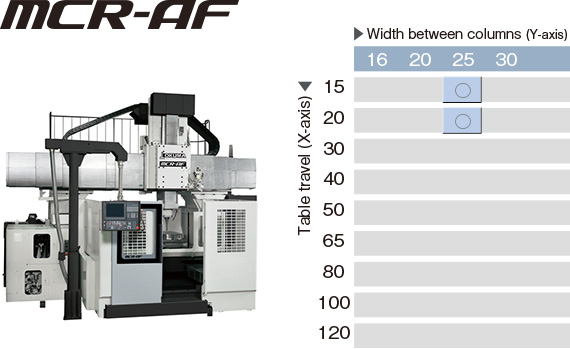

Model lineup

Double-column machining center [5-sided applications]

-

- High rigidity, high output

-

Max axis travels (X-Y-Z):X12,200・Y4,200・Z1,050mm

-

- High function, high accuracy

-

Max axis travels (X-Y-Z):X12,000・Y4,200・Z800mm

-

- Space-saving, cost performance

-

Max axis travels (X-Y-Z):X12,200・Y4,100・Z800mm

-

- Linear motor drive, high speed

-

Max axis travels (X-Y-Z):X5,000・Y3,700・Z800mm

Double-column machining centers (top surface machining)

-

- Space-saving, high speed

-

Max axis travels (X-Y-Z):X2,600・Y2,000・Z800mm

-

- Quill type

-

Max axis travels (X-Y-Z):X5,200・Y2,000・Z450mm

Machine Specifications

| MCR-C | MCR-BⅢ*9 | MCR-A5CⅡ | |||

|---|---|---|---|---|---|

| Travel | X-axis travel (table front/back) | mm | 4,200 to 12,200 | 3,000 to 12,000 | 3,200 to 12,200 |

| Y-axis travel (spindle horizontal) | mm | 3,200 to 4,200 | 2,700 to 4,200 | 2,600 to 4,100 | |

| Z-axis travel (ram vertical) | mm | 1,050[1,250] | 800[1,000] | 800 | |

| W-axis travel (crossrail vertical) | mm | 1,000, 1,200 | 700 to 1,300 | 800 to 1,200 | |

| Effective width between columns | mm | 2,650 to 3,650 | 2,050 to 3,550 | 2,150 to 3,650 | |

| Table to spindle nose (max) | mm | 1,650 to 1,850 [1,550 to 1,750] *1 |

1,350 to 1,850 [1,250 to 1,750] *1 |

1,450 to 1,850 [1,350 to 1,750] *1 |

|

| Table | Working surface | mm | 2,000×4,000 to 3,000×12,000 | 1,500×2,800 to 3,000×11,800 | 1,500×3,000 to 3,000×12,000 |

| Maximum load | kg | 22,000 to 66,000 | 12,000 to 72,600 | 12,000 to 66,000 | |

| T-slots [Width x No. (spacing)] |

mm | 24H7×11, 13, 15 (Center 200) |

24H7×9 to 15 (Center 200) |

24H7×11, 13, 15 (Center 140, 200) |

|

| Height from the floor | mm | 850 to 950 | 800 to 950 | 850 to 950 | |

| Feedrates | Rapid traverse | m/min | X・Y:24, Z:15 (X・Y:24*2, Z:15)*3 (X:20, Y:24*2, Z:15)*4 |

X:15, Y:20*10, Z:15 | X:30, Y:32, Z:20 (X:30, Y:32*2, Z:20)*20 (X:20, Y:32*2, Z:20)*21 (X:30, Y:30*2, Z:20)*22 (X:20, Y:30*2, Z:20)*23 |

| Cutting feedrate | mm/min | 1 to 10,000 | 1 to 10,000 | 1 to 10,000 | |

| W-axis (crossrail vertical) | mm/min | 3,000 | 3,000 | 3,000 | |

| ATC | Tool shank | MAS BT50 | MAS BT50 | MAS BT50 | |

| Pull stud | MAS 2 | MAS 2 | MAS 2 | ||

| Tool magazine capacity | tools | 50 [80, 100, 120, 180] |

32*11 [50, 72, 100, 120, 180] |

50 [80, 100, 120, 180] |

|

| Max tool diameter | mm | W/ adjacent tools:ø135 W/o adjacent tools:ø264 |

W/ adjacent tools:ø135 W/o adjacent tools:ø230 |

W/ adjacent tools:ø135 W/o adjacent tools:ø230 |

|

| Max tool length | mm | 600 | 400 | 400 | |

| Max tool weight | kg | 25 | 25 | 25 | |

| Tool selection | Fixed address | Fixed address | Fixed address | ||

| Spindle | Spindle speed | min-1 | 4,000[6,000] | 4,000[3,600, 6,000, 8,000, 10,000] | 4,000[6,000, 10,000] |

| Taper bore | 7/24 Taper No.50 | 7/24 Taper No.50 | 7/24 Taper No.50 | ||

| Bearing diameter | mm | ø100[ø85*5, ø130*6, ø100*7] | ø100[ø85*12] | ø100[ø85*24] | |

| Motors | Spindle drive | kW | 45/37(30 min/cont) [37(cont)]*5 |

30/22(30 min/cont)*8 [45/37(30 min/cont)*13, 22(cont)*5, 26/22(30 min/cont)*14] |

26/22(30 min/cont)*8 [26/22(30 min/cont)*24, 30/22(30 min/cont)*25] |

| Feed drives | kW | X:14.0, Y:9.4, Z:5.2×2 | X:9.4(14*15), Y:7.3, Z:4.6×2 (X:9.4(14*16), Y:9.4, Z:4.6×2)*17 |

X:9.4(14*26), Y:7.3, Z:5.2×2] | |

| Crossrail traverse | kW | W:4.6(5.2*18)×2 | W:4.6(5.2*18)×2 | W:4.6×2 | |

| Power Requirements | Electrical power supply | kVA | 60*8 | 60*8 | 60*8 |

| Compressed air flow rate | L/min(ANR) | 650(over 0.5 MPa)*8 | 650(over 0.5 MPa)*8 | 650(over 0.5 MPa)*8 | |

| Machine Size | Height | mm | 6,730, 6,980 | 6,250 to 6,850 | 5,820 to 6,300 |

| Floor space (machine only) | mm | 7,810×10,730 to 8,835×27,930 | 6,950×8,200 to 8,700×27,400 | 6,180×8,430 to 7,780×27,930 | |

| Weight (machine only) | kg | 48,000 to 116,000 | 36,000 to 120,900 | 32,000 to 101,000 | |

| CNC | OSP-P300MA | OSP-P300MA | OSP-P300MA | ||

[ ]:Optional

| MCR-H | MCR-AF | MCV-AⅡ | |||

|---|---|---|---|---|---|

| Trave | X-axis travel (table front/back) | mm | 4,200, 5,200 | 2,600 | 2,000 to 5,200 |

| Y-axis travel (spindle horizontal) | mm | 3,200, 3,700 | 1,500, 2,000 | 1,600, 2,000 | |

| Z-axis travel (ram vertical) | mm | 800[1,000] | 800 | 450 (Quill vertical) | |

| W-axis travel (crossrail vertical) | mm | 1,000 | - | 1,000, 1,150 | |

| Effective width between columns | mm | 2,550, 3,050 | 2,600 | 1,650, 2,050 | |

| Table to spindle nose (max) | mm | 1,550 | 1,100 [1,000*29] |

1,360 to 1,510 [1,380 to 1,530]*36 |

|

| Table | Working surface | mm | 2,000×4,000, 2,500×5,000 | 2,000×1,500, 2,000×2,000 | 1,200×1,800 to 1,500×5,000 |

| Maximum load | kg | 22,000, 33,000 | 10,000 | 6,000 to 16,000 | |

| T-slots [Width x No. (spacing)] |

mm | 24H7×11, 13 (Center 200) |

20H7×9, 11 (Center 200) |

20H7×9, 11 (Center 140) |

|

| Height from the floor | mm | 920 | 850 | 700 to 750 | |

| Feedrates | Rapid traverse | m/min | X・Y:30, Z:15 | X・Y:20, Z:10 | X・Y:20, Z:10 |

| Cutting feedrate | mm/min | X・Y:1 to 30,000, Z:1 to 15,000 | 1 to 10,000 | 1 to 10,000 | |

| W-axis (crossrail vertical) | mm/min | 5,000 | - | 420/500(50/60Hz)*37 | |

| ATC | Tool shank | MAS BT50 | MAS BT50[MAS BT50*29, MAS BT40*30, HSK-A63*31*32] | MAS BT50 | |

| Pull stud | MAS 2 | MAS 2*33 | MAS 2 | ||

| Tool magazine capacity | tools | 50 [80, 100, 120, 180] |

24 [32*30*31*32, 48*30*31*32, 50*34, 72*34, 100*34] |

24 [50, 72, 100] |

|

| Max tool diameter | mm | W/ adjacent tools:ø135 W/o adjacent tools:ø230 |

W/ adjacent tools:ø125*34[ø135*35, ø90*30*31*32] W/o adjacent tools:ø230*34[ø125*30*31*32] |

W/ adjacent tools:ø128 W/o adjacent tools:ø230 |

|

| Max tool length | mm | 400 | 400 | 400 | |

| Max tool weight | kg | 25 | 25*34[8*30*31*32] | 20 | |

| Tool selection | Fixed address | Fixed address*34 [random memory*30*31*32] |

Fixed address | ||

| Spindle | Spindle speed | min-1 | 8,000 | 8,000[12,000, 15,000, 20,000, 25,000] | 4,000[6,000, 10,000] |

| Taper bore | 7/24 Taper No.50 | 7/24 Taper No.50 [7/24 Taper No.50*29, 7/24 Taper No.40*30, HSK-A63*31*32] |

7/24 Taper No.50 | ||

| Bearing diameter | mm | ø85 | ø85[ø100*29, ø70*30*31, ø60*32] |

ø100[ø85*24] | |

| Motors | Spindle drive | kW | 26/22(30 min/cont) | 26/22(30 min/cont)*8 [37/26(10 min/cont)*29, 26/18.5(10 min/cont)*30, 30/22(10 min/cont)*31, 15/11(30 min/cont)*32] |

22/18.5(30 min/cont) [22/15(30 min/cont)*5, 22(cont)*42] |

| Feed drives | kW | X:12*27*28(18*27*43), Y:6*27, Z:4.6×2 | X・Y:5.2, Z:3.6×2 | X:3.5(4.2*38, 4.6*39)Y:4.2, Z:4.2 | |

| Crossrail traverse | kW | W:5.2×2 | - | 3.7(AC)[3.6*40] | |

| Power Requirements | Electrical power supply | kVA | 80*8 | 55*8 | 40*8 45*8 |

| Compressed air flow rate | L/min(ANR) | 950(over 0.5 MPa)*8 | 700(over 0.5 MPa)*8 | 500(over 0.5 MPa)*8 | |

| Machine Size | Height | mm | 6,450 | 4,670[4,450*29] | 4,375 to 4,585*41 |

| Floor space (machine only) | mm | 7,825×10,730, 8,425×12,830 | 5,560×4,200, 5,560×5,230 | 4,935×6,000 to 5,335×12,920 | |

| Weight (machine only) | kg | 64,000, 75,000 | 24,500, 26,000 | 19,500 to 30,500 | |

| CNC | OSP-P300MA | OSP-P300MA | OSP-P300MA | ||

[ ]:Optional *1. Asterisk *1 marked square brackets indicate with 250-mm extension head. *2. Deceleration near both ends of Y-axis travel *3. ( ): 30 × 50, 30 × 65, 35 × 50, 35 × 65 machine nominal sizes *4. ( ): 30 × 80, 30 × 100, 35 × 80, 35 × 100, 35 × 120 machine nominal sizes *5. 6,000 min-1 specs *6. 4,000 min-1, high output specs *7. 6,000 min-1, high output specs *8. Standard specs *9. Elevating crossrail *10. Deceleration near both ends of Y-axis travel with 30 and 35 size machines *11. With 32-tool ATC there are limitations to ATC range with 25 and larger size machines *12. 6,000, 8,000, 10,000 min-1 specs *13. 3,600 min-1 specs *14. 8,000, 10,000 min-1 specs *15. 30 × 120 size machine *16. 35 × 120 size machine *17. ( ): 35 size machine *18. 35 size machine *20. ( ): 30 × 50, 30 × 65 size machines *21. ( ): 30 × 80, 30 × 100 size machines *22. ( ): 35 × 50, 35 × 65 size machines *23. ( ): 35 × 80, 35 × 100, 35 × 120 size machines *24. 6,000, 10,000 min-1 specs *25. 10,000 min-1 aluminum machining specs *26. 25 × 50, 25 × 65, 30, 35 size machines *27. Linear motor *28. 25 × 40 size machine *29. 12,000 min-1 specs *30. 15,000 min-1 specs *31. 20,000 min-1 specs *32. 25,000 min-1 specs *33. No pull stud with HSK specs *34. 8,000, 12,000 min-1 specs *35. 8,000 or 12,000 min-1 specs and 50-tool magazine capacity *36. [ ]: 10,000 min-1 specs *37. Auto-positioning crossrail; 400 mm/min for 16, 340 mm/min for 20 size machines *38. 20 × 40 size machine *39. 20 × 50 size machine *40. Auto-positioning crossrail *41. Standard pendant (fixed) and no thru-spindle *42. 10,000min-1 specs *43. 30 × 50 size machine