NEW PRODUCTS 2SP-2500H

- Cycle time minimized with high-speed loading and powerful milling

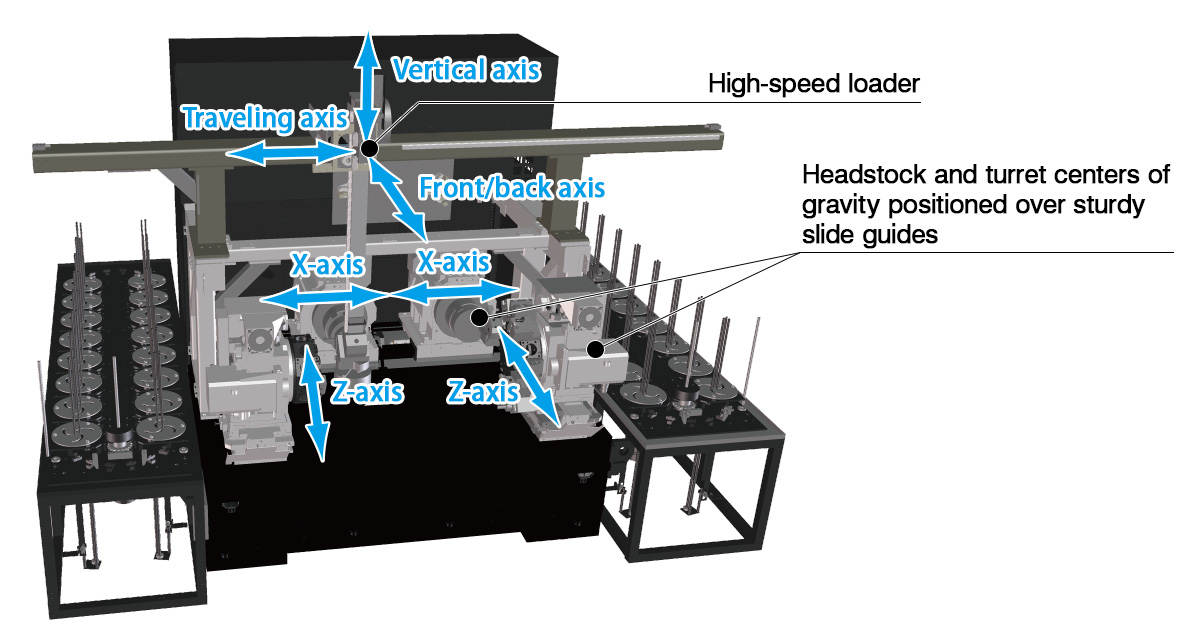

- Machine structure for high-speed loading and powerful machining

- Workpiece load/unload time has been reduced to 4 seconds, and machining-to-part transport line takt time has been minimized. Moving component (headstock, turret) centers of gravity have also been positioned over sturdy slide guides.

Powerful, accurate machining has been achieved with the best machine structure possible for mass production.

-

- Productivity improved with significantly stronger spindle

- The spindles are faster and more accurate with integral motor/spindle drives. The milling tool spindles also have higher output of 7.1 kW, increasing torque to 1.25 times that of the previous machine and doubling end millling capacity to 65 cm3/min. Process-intensive mill/turn operations have become possible.

-

-

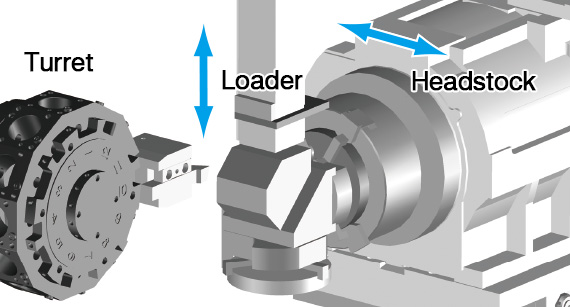

- The shortest line takt times with a high-speed loader

- During workpiece load/unload, the headstock moves to that position. The loader can enter the machine regardless of turret position.

In addition, with servo-driven hand rotation and faster speeds of all movements, workpiece load/unload time of 4 seconds* has been achieved.

* Does not include upper door open/close time.

The load/unload time of 4 seconds is actual data; different operating conditions may require more time. -

Transportable weight 4kg × 2pcs 8kg × 2pcs Workpiece dimensions ø200 × L125 ø250 × L80 -

Long-run, stable machining with high accuracy

-

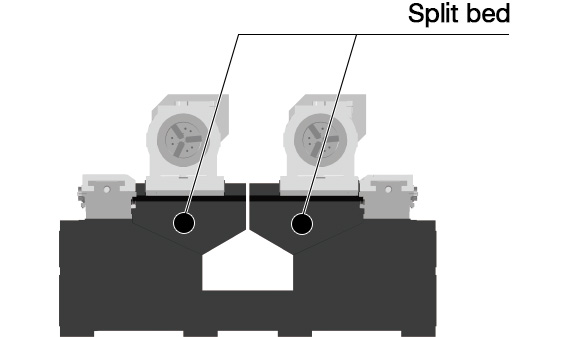

- Split bed for high-quality machining

- A split construction is used for the bed. Transmission of vibration during cutting is inhibited by separating the right and left sides.

This is also effective when high surface roughness is required.

-

Machine Specifications

| Model | Unit | 2SP-2500H (L) | 2SP-2500H (M) | |

|---|---|---|---|---|

| Capacity | Standard chuck size | 8 [10] | ||

| Travels | X- / Z-axis | mm (in.) | 210 (8.27) / 200 (7.87) | |

| C-axis control angle | deg | - | 360 (minimum control angle 0.001) | |

| Spindles | Spindle speed | min-1 | 45 to 5,000 | |

| Spindle speed ranges | 2 auto ranges (2-speed motor coil switching) | |||

| Spindle nose type | JIS A2-6 | |||

| Spindle bore dia/Spindle bearing dia | mm (in.) | ø62 (2.44) / ø100 (3.94) | ||

| Turrets | Turret type | V12 + V12 | Multitasking V12 + Multitasking V12 | |

| No. of turret tools | tools | 12 + 12 | For both L, M 12 + 12 | |

| OD tool shank size | mm (in.) | □25 (0.98) | ||

| ID tool shank diameter | mm (in.) | ø40 (1.57) | ||

| Milling tool | Milling tool spindle speed | min-1 | - | 45 to 6,000 |

| Milling tool speed range | - | Infinitely variable | ||

| Feed rates | Rapid feed rate X, Z-axis | m/min (fpm) | X: 25 (82), Z: 25 (82) | |

| Rapid feed rate C-axis | min-1 | - | 200 | |

| Cutting feed rate X, Z-axis | mm/rev | 0.001 to 1,000.000 | ||

| Motors | Motor spindle | kW (hp) | 15 (20) / 11 (15) (20 min/cont) | |

| Milling tool spindle motor | kW (hp) | - | OSP: 7.1 (9) /4.1 (5) (25 min/cont) FANUC: 5.5 (7.5) (cont) |

|

| Axis drive motors (X / Z) | kW (hp) | OSP: 3.0 (4) / 2.8 (4) FANUC: 2.7 (3.6) / 4.5 (6) | ||

| Coolant motor (50/60 Hz) | kW (hp) | 0.55 ( 0.7) / 0.75 (1) | ||

| Machine size | Machine height | mm (in.) | 3,259 (128.31) (maximum loader height) | |

| Required floor space: length × width (including tank) |

mm×mm (in.×in.) | 2,200 × 2,734 (86.61 × 107.64) (w/o loader) | ||

| Machine weight | kg (lb) | 8,000 (17,600) (w/loader) | ||

| CNC | OSP-P300LA/FANUC 0i-TF [Twin loader specs: FANUC 31i-B] | |||

[ ]: Optional

| Model | Unit | 2SP-2500H (L) | 2SP-2500H (M) | |

|---|---|---|---|---|

| Loader | Transportable parts size (dia × length) | mm (in.) | 4 kg specs: ø200 × 125 (7.87 × 4.92) [8 kg specs: ø250 × 80 (9.84 × 3.15)] | |

| Transportable parts weight × number | kg (ib) × pts | 4 (8.8) × 2 [8 (17.6) × 2] | ||

| X-axis travel (traveling axis) | mm (in.) | 2,838 (111.73) (with work tables on right and left) | ||

| Y-axis travel (vertical axis) | mm (in.) | 750 (29.53) | ||

| Z-axis travel (front/back axis) | mm (in.) | 290 (11.42) | ||

| Rapid feed rate X, Y, Z-axis | m/min (fpm) | X: 180 (591), Y: 110 (361), Z: 48 (157) | ||

| Hand type | Swivel-type double hand, 3-jaw air chuck | |||

| Gripper open/close travel | mm (in.) | ø32 (1.26) (effective travel: ø24 (0.94)) | ||

| Work table | Loaded workpiece diameter | mm (in.) | ø40 (1.57) to ø250 (9.84) | |

| Loaded workpiece mass | kg (lb) | 50 (110) /1 station | ||

| Stacking height | mm (in.) | 450 (17.72) | ||

| No. of stations | 16 | |||

[ ]: Optional